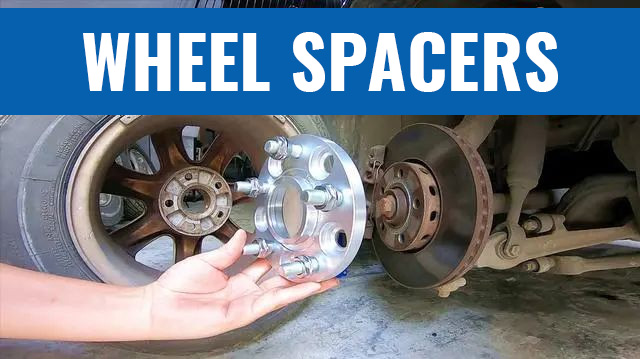

Wheel spacers are aftermarket accessories used to increase a vehicle's track width. They are installed between the wheel hub and the wheel itself, pushing the wheel away from the hub. While spacers can impact various aspects of a car's performance and aesthetics, it is important to understand their limitations and potential effects, particularly concerning the stud pattern.

Understanding Stud Patterns:

The stud pattern refers to the wheel hub's arrangement and the number of bolts or studs. It determines the compatibility between the wheel and the hub, ensuring proper fitment and secure attachment. Common stud patterns include 4x100, 5x114.3, and 6x139.7, where the first number indicates the number of studs/bolts, and the second number represents the pitch circle diameter (PCD) in millimeters.

Effects of Spacers on Stud Pattern:

Increasing Track Width: By pushing the wheel away from the hub, spacers effectively widen a vehicle's track width. This can enhance stability, cornering grip, and overall handling characteristics. However, it is crucial to use appropriately sized spacers to maintain compatibility with the existing stud pattern.

Potential Modifications: In some cases, installing spacers may require modifications to the wheel studs or bolts. If the spacer thickness exceeds the length of the wheel stud, longer studs or bolts might be necessary for proper engagement and safe installation.

Adverse Effects: Using incorrect or poorly designed spacers can lead to undesirable consequences. For instance, if the spacer does not align correctly with the stud pattern, it can cause uneven pressure distribution on the studs, resulting in weakened structural integrity. This could lead to wheel separation or failure while driving, posing a significant safety risk.

While wheel spacers can alter a car's track width and provide certain performance benefits, they should be used with caution. It is essential to select spacers that are specifically designed for the vehicle, ensuring compatibility with the existing stud pattern. Additionally, professional installation and periodic inspections are crucial to maintain the safety and integrity of the wheel assembly.