Fuel Pump Maintenance and Maintenance Recommendations

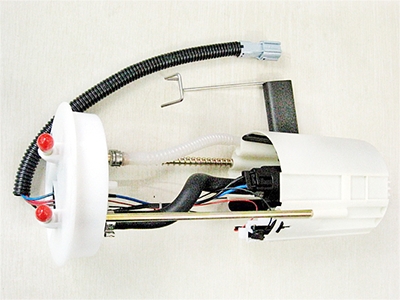

Specify the interval for fuel filter replacement: Regularly replace the fuel filter according to the manufacturer's recommendations or the guidelines in the vehicle manual. This helps prevent contaminants from entering the fuel pump and damaging its internal components, ensuring fuel purity.

Check the fuel pump supply pressure: Periodically inspect the fuel pump's supply pressure using appropriate testing equipment. If an incorrect supply pressure is detected, repair or replacement of the fuel pump may be necessary.

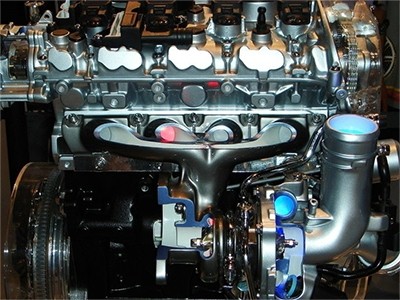

Clean the fuel system: Perform regular cleaning of the entire fuel system, including the fuel pump, injectors, and fuel lines. Accumulation of carbon deposits and sediment can lead to a decline in fuel pump performance, so using specialized fuel system cleaning agents is essential.

Regularly inspect electrical connections: Check the electrical connections of the fuel pump for proper tightness and signs of corrosion or damage. Ensure all wiring is secure and reliable, and repair or replace any damaged electrical components.

Periodically check the fuel pump seals: Ensure that the seals of the fuel pump are intact and free from leaks. If any leaks are detected, immediate repair or replacement of the seals is necessary to prevent further damage and fuel wastage.

Focus on fuel quality control: Use high-quality, clean fuel and avoid low-quality or contaminated fuel. Poor-quality fuel can contribute to the formation of carbon deposits and sediment, adversely affecting the fuel pump.

Pay attention to fuel pump temperature: Excessive temperatures can have a negative impact on the fuel pump. Ensure proper functioning of the cooling system around the fuel pump and avoid overheating.

Avoid prolonged operation with low fuel levels: Fuel pumps typically rely on lubricating oil for cooling and lubrication. Prolonged operation with low fuel levels can result in insufficient lubrication, causing damage to the fuel pump.

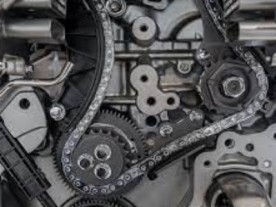

Use the correct lubricants: Apply appropriate lubricants on lubricated components and follow the manufacturer's recommendations for lubrication. This helps reduce wear and friction, providing effective lubrication and cooling.

Perform regular maintenance of the entire fuel system: Regularly conduct comprehensive maintenance of the fuel system as per the manufacturer's guidelines, including inspecting and cleaning the fuel pump, injectors, fuel tank, and fuel lines.

Follow operating specifications: Adhere to the operational guidelines provided in the vehicle manual, including correct procedures for engine startup and shutdown, avoiding sudden acceleration or braking to minimize unnecessary stress and damage to the fuel pump.