The Fuel Pump Assembly in Hybrid Vehicles

The fuel pump assembly in hybrid vehicles plays a crucial role in the overall energy conversion system. It is responsible for delivering fuel from the tank to the internal combustion engine, ensuring a stable and reliable fuel supply.

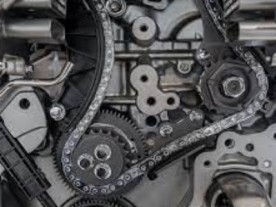

Key Components:

- Internal Combustion Engine Fuel Pump: Hybrid vehicles still utilize internal combustion engines as one of their power sources, necessitating a fuel pump to transport fuel from the tank to the engine.

- Electrically Driven Fuel Pump: Hybrid vehicles are also equipped with electrically driven fuel pumps that supply fuel to the internal combustion engine. These pumps typically consist of an electric motor, pump body, and control circuit.

- Fuel Control Unit: The fuel pump assembly includes a fuel control unit responsible for monitoring and adjusting the working parameters of the fuel pump. This unit receives signals from the vehicle's control system and modulates the pump's output based on real-time demands.

- Fuel Filter: The fuel pump assembly commonly incorporates a fuel filter to remove impurities and particles from the fuel, safeguarding other components of the fuel system.

Features:

- Electronic Control: The fuel pump assembly in hybrid vehicles employs advanced electronic control systems, enabling precise fuel injection control and variable fuel supply capabilities. This enhances fuel economy and reduces emissions.

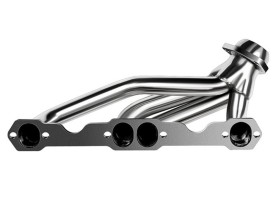

- High-Pressure Direct Injection Technology: Hybrid vehicles often employ high-pressure direct injection technology in the fuel pump assembly, which allows fuel to be injected into the combustion chamber at higher pressures. This improves combustion efficiency and power output.

- Fault Diagnosis and Safety Functions: The fuel pump assembly is equipped with fault diagnosis systems and safety functions to monitor its operational status and promptly alert to any issues, ensuring vehicle safety and reliability.

- Energy Efficiency and Environmental Friendliness: The application of the fuel pump assembly in hybrid vehicles helps reduce fuel consumption and emissions, improving energy utilization efficiency and meeting environmental protection requirements.

Future Development Trends:

- Advanced Electronic Control Systems: Future fuel pump assemblies will rely on advanced electronic control systems for finer fuel injection and more efficient energy management, meeting evolving energy efficiency demands.

- Remote Connectivity and Intelligent Features: Fuel pump assemblies may integrate with a vehicle's remote connectivity system, enabling remote monitoring and fault diagnosis for enhanced maintenance efficiency. Intelligent features will also be applied, providing a smarter and more convenient driving experience.

- Efficient Energy Conversion Technologies: With technological advancements, fuel pump assemblies may adopt more advanced techniques such as high-pressure direct injection and variable valve lift control, further enhancing energy conversion efficiency and power output.

- Integration of Renewable Energy Sources: As renewable energy sources continue to develop, fuel pump assemblies may integrate with battery systems, solar charging, and other energy sources to achieve diversified and sustainable energy supply options.