These are common symptoms of a potentially bad fuel pump:

1. A lack of power when “under load” (at highway speeds or laden with people/cargo).

2. An engine that is hard to start or won’t start.

3. An engine that “chokes out” or dies after running for a while or up to temperature.

4. A check engine light that returns a lean code from the engine’s computer.

5. A whining noise from the fuel tank area (usually under the rear seat or at the rear of the vehicle).

But, with the exception of a whining noise from the fuel tank, these are also symptoms of problems with a half dozen other systems. Determining if a fuel pump is to blame for a lack of power under “load” is often about ruling out other possible issues.

Here’s how you go about diagnosing fuel system problems, so that you can determine if you need a fuel pump or not.

Figure Out The Type Of Pump You Have

Your first step in diagnosing a fuel pump problem: Figuring out if your vehicle has a mechanical fuel pump or an electric fuel pump.

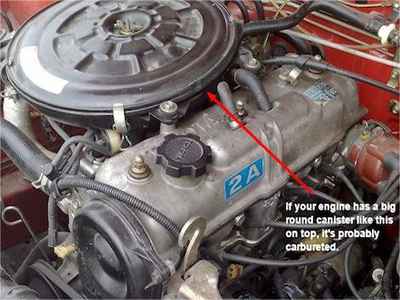

Carbureted vehicles have mechanical fuel pumps, with few exceptions. So, if your vehicle has a carb, you probably have a mechanical fuel pump.

On most vehicles made after 1990 (and quite a few made after 1986), the fuel pump is likely electric and located inside the fuel tank.

HINT: If your vehicle has a large air cleaner (filter) on top of the engine to filter air going into the engine, you likely have a carbureted engine.

If your vehicle has a mechanical fuel pump, it’s unlikely that the fuel pump has failed. This is because mechanical pumps tend to fail entirely…if you have a mechanical fuel pump with a problem, your engine isn’t getting any fuel at all. There’s no such thing as an intermittent mechanical fuel pump failure.

In a fuel injected engine, electric fuel pumps can fail intermittently. So, if your vehicle has an electric fuel pump, you’ll have to keep digging.

Pressure Testing An Electric Fuel Pump

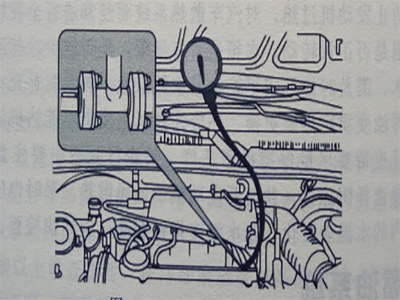

The most effective option for testing for fuel pump failure is to attach a fuel pressure gauge to the common fuel rail on a fuel injected engine. A shop manual or vehicle repair manual will have fuel pressure specs at various RPM rates, with tolerance ranges. Testing pressure in the lines between the fuel pump and the fuel pressure regulator will confirm either a pump failure or point toward a faulty regulator. If the measured fuel pressure is not within those parameters, the pump may be faulty.

NOTE: Cheaper fuel pressure gauges are prone to data errors, so it is recommended to use high-quality testing tools.

If the vehicle will not start at all but the engine will crank (turn over without starting) when the key is turned, the problem could be fuel delivery. Again, testing for fuel pressure can determine whether this is the case.

Finally, if your vehicle engine is sputtering or dying out after running for a while without a problem, diagnosis can be tricky. This usually happens when the engine spends some time at cruising speeds and is then slowed down at a stop light or stop sign. In this scenario, the engine can sputter for more reasons than we can list.

However, if you have a sputtering engine and a “lean mixture” check engine code, that may indicate a fuel pump problem. The diagnosis process here is to bring the engine up to temperature and then do a fuel pressure check.

Replacing the Fuel Pump

Replacing a faulty fuel pump is not a simple task. It involves dropping the fuel tank, removing and replacing the fuel pump assembly, and then testing all work. A fuel pump replacement should also be accompanied by a fuel filter replacement and a check of the pump’s connectors (on both sides of the plugs) to ensure they are not burnt or overworked.

When you purchase our fuel pump replacement, we will offer high-quality after-sales service to solve your problem (installation, quality or any other). Meanwhile, if you are not so familiar with replacing fuel pumps, we strongly recommend seeking help from professionals.